Our first stop was Persea Tree Nursery in Fallbrook, a nursery & greenhouse facility that grows, grafts and sells avocado rootstocks to groves and orchards.

As we toured through the facility, including an "avocado dark room" & swelteringly hot greenhouse (the humidity helps these young plants — which are native to the tropics — thrive,) I picked up on these fascinating tidbits:

- a single avocado pit can supply enough energy to start up to 6-7 plants.

- when properly cared for, a tree can start producing edible fruit in 2 years.

- when stressed, the trees have a tendency to bear fruit on alternate years - resulting in a cycle of high & low yields (and consequently, prices in the market.)

- 95 percent of avocados produced in California are of the Hass variety (I knew they are the most popular, but wasn't aware of how big a majority they made up; meanwhile, I'm crossing my fingers for the giant, round Reeds - my favorite varietal - to take up more of the market share & be more readily available.)

In addition to these facts, we learned how these the nursery grows the plants from seeds, eventually grafting them onto hearty roots & eventually prepare them for shipment to the orchards.

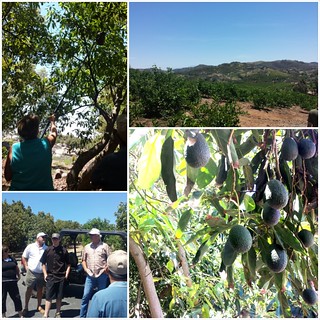

After breaking a sweat in the greenhouses, I was glad our next stop, Sierra Pacific Farms in Temecula, took place underneath the shade of fully grown trees. There, we were shown how these mature trees are maintained, pruned and picked.

Fun facts from this part of the tour:

- The trees can grow to 40 feet tall, but since the fruit have to be hand-picked while they are still on the branches, they are usually pruned back to 20 feet or less.

- Related to last fact, fallen fruit does not go to market, since it violates food safety regulations & the fruit is likely bruised from the impact.

- Avocado fruits mature, but do not ripe, while they are still on the tree - which give the farmers a bit of leeway in when to pick. Of course, it would still be susceptible to other forces of nature (pests, sun, wind and of course, gravity.)

A few of us had a chance to get hands-on the avocado picker (basically, a pole with a pouch & snips attached), but none of us can compare to the pros - who can fill a 900-pound bin & then some)in a day's work.

After the brief hike & tour of the grove, we had an al fresco, avocado-centric lunch catered by Sorrel Bistro. As we were feasting away, registered dietician Katie Ferraro talked about some of the nutritional benefits of avocados (though I'm amused at the idea of one-FIFTH of an avocado being classified as a standard serving, when I can easily polish half a fruit—including Reeds—in one sitting.)

Katie also demo'd the new way of cutting & peeling avocados, so you don't have to risk injuring yourself with that knife-thwack on the pit and so you can easily access the most nutritious parts of the fruit (the skin-adjacent, jade-hued flesh.)

As for the lunch itself, I'm impressed with the versatility of the fruit throughout the meal -- particularly with the turkey avocado burger (with avocado meshed into the patty, which I think helps keep it moist) + avocado'd tater tots and the avocado panna cotta. At the same time I also enjoyed the simple preparations, such as a crostini with bacon bits, avocado mash & bay scallops.

Bellies full, we were then bussed (& given a napping opportunity) to Westpak Avocado, a high-tech avocado processing & packing facility in Murrieta. There, we were given a tour of pretty much the entire operation, from when the fruits first arrive in said 900-pound bins from the groves, to when they get boxed & packaged and ready to shipped out.

Here, the parts that amazed me most were:

- They have "JustRipe" lockers that can warm, condition & cool pallets of avocados so they are at their recipients' requested level of ripeness when they get shipped out.

- The avocados are inspected by humans and machines (which takes 22 shots of each avocado that passes on by) for quality & size.

- That they hotwash their shipping bins in what looks like a supersized industrial dishwasher, to sterilize -obviously- but to also minimize risk of soil contamination between groves.

Most importantly, they have an impeccable-looking traceability system that can quickly track fruits back to the grower(s), so in case something goes awry - an investigation & possible recall can take place in a timely manner (and they have conducted mock recalls where they can ID which cases are suspect in one hour, impressive for a place that processes 40,000 pounds of avocado each day!)

Of course, this tour concluded with us getting plenty of avocados to take home (along with a few other goodies,) which I put to swift use in one of my super-simple, longtime favorite from childhood:

An avocado, spinach & mayo sandwich. Of course, with all the avocados I have -- I'll definitely concoct something a little fancier to post as a recipe. But in the meantime, you can get inspired by the recipes California Avocado Commission's site.

More photos on flickr set here.

More photos on flickr set here.

No comments:

Post a Comment